GUEST ARTICLE

Industry Insights from NIZO: Using and optimising membrane filtration for extracting plant proteins

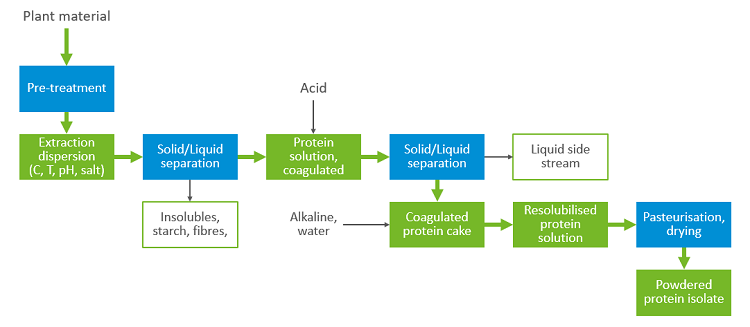

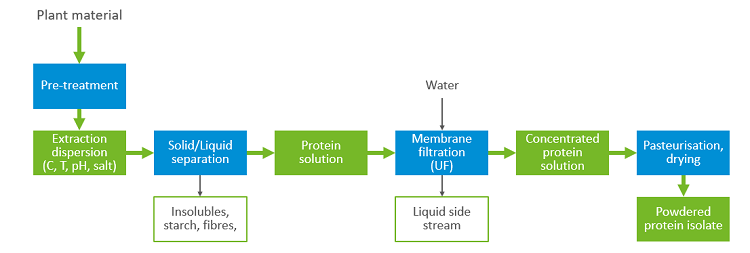

To turn a protein source – such as dairy or plant material – into a viable protein ingredient, you must separate the protein you want from the various molecules you do not. Membrane filtration has proven itself as a protein extraction technology in the dairy industry; now players in the plant protein field, whether start-ups or established manufacturers, are also taking a closer look.

It’s a technology offering clear benefits – if you can overcome the challenges, as Fred van de Velde, NIZO’s Expertise Group Leader Protein Functionality, explains.

René Floris: What is membrane filtration, and what are its benefits?

Fred van de Velde: With membrane filtration, you filter your material stream through a polymer (or in some cases ceramic) membrane. Pores in this membrane enable smaller molecules to pass through and be flushed away, while the larger, protein molecules are retained. Membranes come in a range of materials and pore sizes, and offer several benefits compared to acid precipitation - another protein extraction technology that is often used in plant protein production.

RF: What are the benefits of using membrane filtration?

FV: Firstly, membrane filtration gives you higher yields because you recover practically all of the protein, which is not the case with acid precipitation. Secondly, your protein retains its functionality better with membrane filtration. Thirdly, it is a more environmentally friendly technique: acid precipitation uses both a base and acid, resulting in a salt side stream, and a product containing a relatively high salt content. Membrane filtration, on the other hand, uses plain water to flush away unwanted molecules. Finally, you can get a highly concentrated protein solution, which requires less energy in the final drying stage, saving costs and delivering another environmental benefit.

RF: What are the challenges of using membrane filtration?

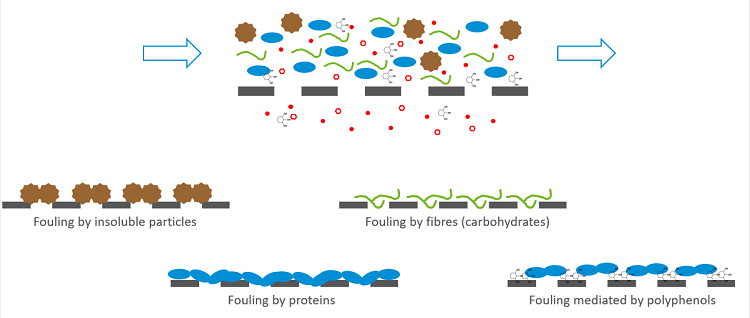

FV: During protein extraction, residue builds up on the membrane, reducing its filtering capacity. The rate of this fouling build-up depends on the membrane pore size and the interaction occurring between your source material and the membrane material. This happens with both dairy and plant proteins. However, in the dairy industry, processes for minimising fouling and cleaning have already been well-optimised. In many ways, dairy is rather straightforward: you are dealing with one type of product (milk), all components in the milk are well solubilised, and its behaviour is understood, thanks to the industry’s long history. But with plant proteins, there is much more complexity: there are many different protein sources, each of which behaves in a different way, and these varying behaviours are not yet well-understood. So, if we want to reduce fouling, and thereby decrease cleaning, downtime, etc., we need to understand much more about the mechanisms causing that fouling residue layer from plant proteins.

RF: What causes fouling of membranes by plant proteins?

FV: Based on our experience at NIZO with membrane filtration and plant proteins, we have identified a number of mechanisms that can cause a build-up of residue on membranes. The first is insoluble components in your starting material, which may block the membrane pores. This of course isn’t a problem with dairy/milk, which is made up of soluble components. Plant material also contains non-protein fibres, which can block the pores, as well. Another potential mechanism is protein adsorption or even unfolding of the proteins on the membrane, which may cause fouling. Furthermore, polyphenols, which are also abundant in plant foods, can interact with proteins, potentially accelerating the formation of the fouling layers.

RF: How do you select the ‘right’ membrane to use

FV: Before beginning production, you can test different membranes to see which results in the least fouling. While it isn’t possible yet to say “you are using this plant protein source, therefore, this type of membrane will probably be best for you”, knowledge of membranes and plant proteins might help you get a good start in choosing which options to test. For example, we know that fava beans contain more fibre than pea, which might result in more fibre-related fouling. Sunflower and rapeseed, on the other hand, are high in polyphenols: this could thus result in more polyphenol-related fouling.

RF: How can plant-protein manufacturers optimise their use of membrane filtration?

FV: By analysing the fouling layer and finding strategies to minimise the impact in the upstream processing. For example, if the main problem is insoluble components, it may be solved with either centrifugation or microfiltration. If the fouling layer is predominantly carbohydrate-based, you could use enzymes to break them down. The resulting smaller elements are thus more easily washed away. But there is still a lot of work to be done to optimise plant protein production processes using membrane filtration.

RF: What impact can this optimisation have on the processing?

FV: We have seen excellent results optimising processes using membrane filtration in the dairy industry – even though this is already a well-established industry. For example, we did an optimisation for dairy-based infant formula, and were able to significantly improve the ratio between running time and cleaning time. This increased the factory’s production capacity by 40%. Based on results such as this, we are confident that making the effort and investment to optimise plant protein processing using membrane filtration will also deliver sizable improvements.

RF: What are the next steps for improving the use of membrane filtration for plant proteins?

FV: We have already identified several potential mechanisms of fouling, but to select the best membrane and to design countermeasures, we need to understand which one is dominant when processing a certain plant material. In addition to supporting our clients with selecting and optimising specific protein/membrane combinations, NIZO is working to set up a consortium of industrial partners, to build more robust knowledge and to test certain hypotheses. Does a specific type of fouling happen with all plant proteins, or only with certain plant proteins? What is the role of the non-protein material in the plant product? We need more scientific insight, so that we can then, for instance, divide proteins by possible mechanisms, validated by research. That is the key next step.

In NIZO's next article, the research organisation will look at how to deal with ‘co-passengers’ like polyphenol when isolating alternative proteins.