Industry looks to upcycled ingredients as food price crisis bites

“For the first time in decades we are realising international trade is not a given any more,” Bühler Group CEO Stefan Scheiber told a media briefing at the supplier’s Networking Days event at its headquarters in Uzwil, Switzerland.

Supply chain disruption caused by COVID and the war in Ukraine are, among other things, creating a “pull back of globalisation” which we’ve long taken for granted, he warned. “All of a sudden everything is scarce. Any normal thing, all of a sudden is a problem.”

A solution? Upcycled ingredients. At the event Bühler unveiled a host of new tie-ups in the plant protein, cell-based protein and biotech space all intended to help its customers find solutions to cut their energy, waste, and water impact.

Valorizing brewers’ side streams

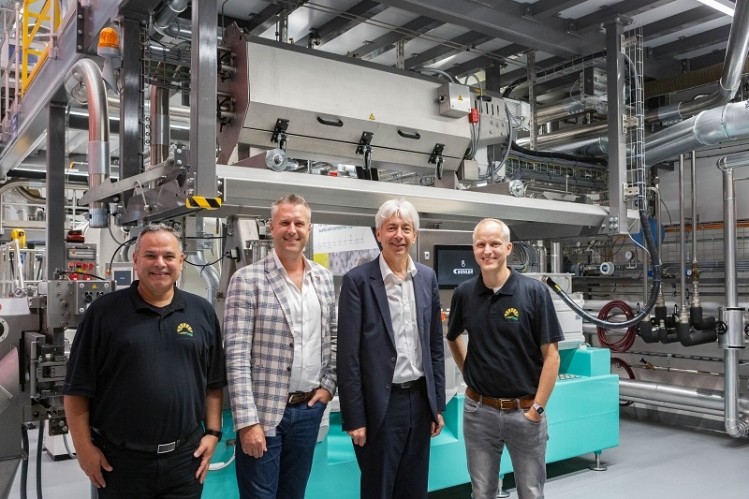

Bühler unveiled a joint venture with CN & Partners to create Circular Food Solutions Switzerland, a new company which will produce an ingredient intended for use in meat alternatives based on upcycled spent grain from Switzerland.

Upcycling, a process by which by-products and waste materials are transformed into new materials or products that have greater value, is the “holy grail of the circular economy”, the venture announced. In the beer brewing process, the starch of the barley malt is used to produce beer. The leftover is known as spent grain. Traditionally this is used as feed for animals. But much of the nutritious part of the grain remains is in this spent grain.

The company, which expects to start operations by summer 2023, will first source barley from around 150 Swiss farmers. It will sell that to that to local brewers, then buy back the spent grain to produce a plant-based meat substitute ingredient. It will also buy back any remaining spent grain to use as biochar to return to the fields where the barley is grown, reducing fertiliser use by up to half.

"I believe that local production is a key element for all the problems we're seeing,” said Swiss entrepreneur Christoph Nyfeler, owner of CN & Partners.

“By providing malt to the local brewers and buying back the spent grains we can eliminate one of the key problems for local production inside and outside Switzerland. We can eliminate the cost factor. Yes, local production is more expensive, but if I have an opportunity to buy the waste back at an acceptable rate, I can give an economic benefit to the brewers.”

Other ingredient suppliers and manufacturers are keen to tap into elegant circular economy solutions. Dole Sunshine Company (DSC), for example, is turning fruit waste into fibres to create fashion products. This helps the company limit its CO2 emissions by preventing banana stem waste from reaching landfills. It also helps improve the livelihoods of those local communities making the banana textile fabric.

These types of solution appear popular with consumers too. Launches of food and beverages containing upcycled ingredients rose by compound annual growth rate of 122% in the five years to 2021, according to a report from Innova Market Insights. This figure was higher than products using recycled plastic in packaging (59%) and those carrying carbon-emissions claims (47%).

Nearly half of consumers surveyed by Innova added they are actively trying to cut food waste. Some 62% said they are willing to pay more for food and beverage products that are dedicated to stopping food waste.

But is climate action affordable during a cost of living crisis?

Inflation is obviously another huge pressure impacting manufacturers and consumers. Many commentators have suggested sustainability goals should take a back seat in the face of food price fears. Tellingly, the cost of living crisis has overtaken climate change as the leading concern of Millennials and Gen Z for the first time, a UK survey recently revealed.

But Peter Bakker, President and CEO at the World Business Council for Sustainable Development (WBCSD) -- which wants to minimise the environmental footprint of the global food system -- told FoodNavigator that the cost of living crisis across Europe is an opportunity to futureproof the food sector.

“The more climate sustainable you can make the food system, the lower the energy bill in that system will be,” he said. “So it could actually serve as an accelerator to reduce energy use emissions in the system and that's where I think the focus should be.”

Some countries are now firing up their coal power plants to avoid gas shortages, he noted. “But the real incentive is to accelerate towards renewables because then you get what you want geopolitically in terms of less dependency [on Russian gas] but you will also reduce emissions and therefore the cost in the food system.”

He added: “This is not the time to discuss move to the true price of food and start taxing meat or other elements that are intense in emissions because in a time of inflation people are having difficulty enough paying their bills. We want to change the supply chains to drive costs out while making it more sustainable. It's a longer-term gain."