NoPalm Ingredients: Meet the ‘circular by nature’ start-up disrupting tropical oils with microbes

NoPalm Ingredients is on a mission to disrupt the palm oil industry with microbial oil alternatives.

The start-up was founded in Ede, the Netherlands, by two entrepreneurs – CEO Lars Langhout and CTO Jeroen Hugenholtz – with ‘purpose’ front of mind.

Deforestation is a ‘big part’ of the climate problem, explained Langhout. “If you go to Indonesia or Malaysia and see the vast amount of palm plantations, and consider that it all used to be tropical rainforest, it’s mindboggling.”

Despite deforestation, biodiversity, and climate concerns, palm oil continues to be a sought-after commodity. Approximately 50-70% of all packaged products in the supermarket contain palm oil. “It’s in our food, clothes, detergents, and fuel that powers our cars,” explained the start-up. “We each consume, on average, eight kilograms of palm oil every year.”

At the same time, global populations are on the rise and predicted to reach 9bn by 2050. The number of people following a Western diet, too, is growing. “You can easily do the math that there will be much more rainforests being cut or burnt down to make room for palm oil plantations,” stressed Langhout.

The co-founders feel ‘obliged’ to step in with a sustainable alternative to the contentious commodity and are doing so with microbial oils.

‘Circular by nature’

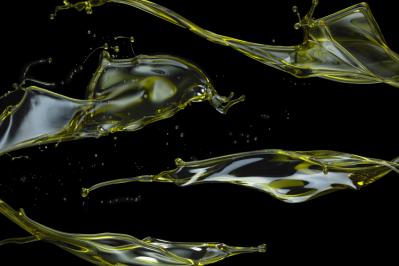

NoPalm Ingredients’ solution is designed to replace the use of palm, and other tropical oils, in food, cosmetics and detergents.

“We’re ‘brewing a better world’ by providing food and cosmetic companies with substitutes, using fermentation technology,” said Langhout. The result is microbial fats and oils.

The start-up’s approach is anti-waste and ‘circular by nature’. It crushes side streams such as potato peels, rejected vegetables, or any other biomass that contains either sugar, organic acids, or alcohol, to ferment with yeast.

Without revealing the specifics of the stain, the CEO said they’re using a ‘wild yeast strain’. “We’ve used Directed Evolution technology to increase the yield and ensure it has the properties that are beneficial for our process. We’ve selected multiple strains that way. It’s non-GMO, which is a key differentiator.”

The yeast fills with lipids, which are harvested and used as a substitute for tropical oils.

Once the microbial oil is separated from the biomass, the start-up is keen for the biomass itself to be repurposed. “Not only are we using side streams as a feedstock, but 90% of what we’re using is left as a residual biomass that can be further upcycling or back into the value chain.

“The biomass that’s left contains protein, vitamins and yeast extracts, which could be downcycled into animal feed or upcycled [into other valuable products].”

Philosophy behind ‘NoPalm’ explained

There are other benefits to the start-up’s technology, including its suitability for localised food production.

In leveraging side streams as feedstock, its technology is ‘widely applicable, anywhere in the world’. Side streams can be leveraged from the US, Japan, Africa, Europe, or the Middle East, we were told. “It doesn’t really matter, as long as they contain sugars, organic acids, or alcohols”.

The other is that NoPalm Ingredients’ fats are ‘tuneable’, which Langhout explained the company has already demonstrated.

“We can make a fat that is solid at room temperature, an oil that’s liquid at room temperature, and we know we can make different variations on the fatty acid profile.”

Being able to modify the fatty acid profile is important, because NoPalm Ingredients is working on a ‘host’ of ingredients and doesn’t actually aspire to develop a ‘direct palm oil substitute’.

Palm oil is favoured by food manufacturers for a variety of reasons. It is high yield, neutral in colour and taste, and versatile. If it wasn’t for palm oil’s muddied reputation, Langhout believes every food maker would use it. With PR in mind, some have turned to alternatives such as soybean or coconut oil, he explained.

If NoPalm Ingredients can produce a viable alternative for palm oil at-scale, then the start-up is indirectly finding a solution for these alternatives as well, he suggested.

“It’s not a matter of making a direct palm oil substitute, we want to be having conversations with our customers and providing them with the fatty acid profile they need, so that they no longer require tropical oils.

“No deforestation would be required to provide them with the fatty acid profile they desire. And it would be abundantly available.”

But is all palm oil bad?

Palm is present in a wealth of products, both in food and non-food categories. Aside from the perhaps more obvious confectionery and ice cream products, it’s also in pizza, infant formula, noodles, pasta, toothpaste and soap.

“When I started exploring this industry, I was baffled by the number of products it’s in,” recalled Langhout.

Of course, just because a product lists palm oil in its ingredients list does not mean it is associated with deforestation. Many food brands have achieved, or plan to achieve in the near future, a 100% certified sustainable palm oil supply chain.

If NoPalm Ingredients is looking to disrupt the entire palm oil industry, we asked its CEO whether responsibly produced palm oil should still have a place in the sector.

“If it’s a choice between sustainable palm oil and unsustainable palm oil, I’d say yes,” responded Langhout.

However, sustainable palm oil is not a perfect solution, he explained. “Deforestation aside, sustainably produced palm oil still requires the use of chemicals. It still relies on transportation. And if we’re honest, it remains a monoculture for which fertilisation is required to keep up plantation yields. If you look at the fertility of the soil, it’s almost dead.”

In an ideal world, no palm oil – whether sustainably produced or not – would be used, he continued.

From a practical perspective, Langhout would want to make sure unsustainable palm oil production is ceased immediately, before sustainable palm is replaced.

“There is no argument as to why palm oil plantations should continue to run in the long-term. We have a solution that’s local, which can leverage local supply chains to produce it, doesn’t require deforestation or transportation, and limits the use of chemicals.”

Business strategy

NoPalm Ingredients expects its first microbial fat-based ingredients will reach the market in 2025, which is also when it plans to establish its own commercial facility.

Before that happens, the start-up will need to receive regulatory approval from relevant agencies. NoPalm Ingredients is starting with the US Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA).

“We’re confident we’ll achieve [Novel Foods] approval, since our oils have a similar fatty acid profile to palm oil. The output is more or less the same, it’s the origination that is different.”

Another barrier to commercialisation is scale. However in this instance, too, the start-up is moving in the right direction. Currently fermenting at 100L scale, it is planning a 4,000L fermentation in September. “This year is all about demonstrating that we can do this at scale,” the CEO explained.

“I think we’re quite advanced in terms of scale. The next step will be to complete our next fundraise, work with more side streams, and expand our product portfolio.”

After that, the start-up will set up pilot projects with customers and collaborations with suppliers before moving into commercialisation.

NoPalm Ingredients has a two-pronged business model.

One the one hand, the start-up plans on collaborating with suppliers which don’t currently work with palm oil, but who have ‘large volumes’ of side streams. Together, the partners could produce NoPalm Ingredients offerings.

At the same time, the start-up is keen to establish a licencing model for businesses – such as food manufacturers – which currently source palm oil but which also produce large volumes of side streams. Under this agreement, the company in question could convert their side streams into microbial oil themselves, and replace palm oil ‘altogether’ in their processes, we were told.

“Imagine if all companies in the world started using microbial oil instead of palm oil. We could make a real impact and eliminate palm oil in an accelerated way.”