The future of cell-based protein: ‘Food manufacturers should look at this as an opportunity’

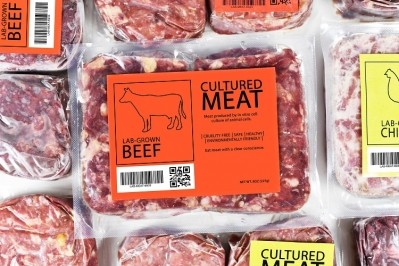

Cell-based agriculture can create products from cell cultures as opposed to whole plants or animals. The technology has generated a ‘huge amount of investment and interest in the last few years’, according to IFF Taste global marketing director Karen Stanton.

Introducing a panel on the rapidly emerging space, Stanton stressed that cell agriculture has attracted more than US$700m-worth of investment - $400m of which was pumped into the sector in 2019 alone.

The excitement around cellular agriculture largely stems from the benefits and disruptive potential on offer.

Innovators in the field believe that, when compared to conventional animal agriculture, the production of animal tissue in bioreactors will prove a safe and more sustainable source of protein. Cellular agriculture, it is hoped, will offer a means to meet the rising appetite of the growing global population, projected to reach 9bn people by 2050, without exhausting finite natural resources and raising carbon emission levels.

Isha Datar, president and CEO of donor-funded research institute New Harvest, noted that cellular agriculture has ‘really grown in the last five years’. “We are in a technically capable place to be producing food products from cells and we are also at a place in the world where we are trying to address food sustainability and food security with technology. Cellular agriculture is a great way for us to avoid a lot of the challenges that come from animal agriculture to create a better food system,” she suggested.

The road to market: ‘This is much bigger than a hamburger’

While rapid scientific advances and technological developments make today an exciting time for cellular agriculture, there are some major challenges to overcome before a product reaches the mass market.

“The biggest barrier to entry for the field right now is that it is not fully fledged yet. We have some companies that are well supported but we don’t have a very robust academic environment that talent would come through to populate those companies… This is much bigger than a hamburger. This is a whole new field of research, a whole new industry, a whole new way to produce food. We need to fill out a lot of the gaps in making that happen.”

One such gap is cost – and in particular the expense of growth mediums and difficulty producing at scale – that push up the expense of cellular meat production.

Ahmed Khan, founder of CellAgri, noted that some of the cultured meat companies have said they expect to bring products to market within a matter of years. However, he stressed, it will be crucial for these products to be high quality and safe.

“For some food companies there are still hurdles that they have to be address first to get from bench scale to commercial scale before launching a product to market. Several of the meat companies have shared timelines of producing product over the next few years, some as early as 2021. But, in the bigger picture for the field, it is more important that the first products that come to market come out correctly rather than faster in terms of safety and public perceptions,” he observed.

Datar – who co-founded cultured dairy business Perfect Day and cultured egg producer Clara Foods – believes that these products are much closer to scale. She sees significant upside in leveraging cellular technologies to produce protein products such as egg and dairy – and believes that these developments will have a bigger impact in the short term.

Held on 17th June, the event was organised in support of IFF’s Re-Imagine Protein innovation programme. IFF aimed to differentiate the one-off Plantful Virtual Festival by delivering ‘insights and inspirations’ on plant-based food and drink products across two virtual stages. The company worked in cooperation with external experts and knowledge partners from around the world to develop content.

Describing the approach IFF took, Mahbir Thukral, Marketing Manager of Innovation, told FoodNavigator: “Like many, during these disruptive times we’ve been overwhelmed by the vast number of invitations to digital conferences, seminars and webinars. With our virtual festival concept, we wanted to turn the very notion of digital event on its head. We had strived to capture the essence of an immersive, multi-sensorial festival rather than your mainstream suit-and-tie conference.”

“The future of those products is a lot sooner than meat from cell cultures. And that is because we have already been producing various foods from cell cultures for a long time. A lot of vitamins, a lot of food additives are already produced from cell cultures.

“What is new about Clara Foods and Perfect Day Foods is that they are producing commodity level products. The volumes that we are talking about are much higher. In some ways the regulatory system is more set up for this type of protein products.”

Looking at the development of the cellular agriculture market, Datar suggested Perfect Day ice cream will be available ‘this year for sure’.

She believes that the shift to cell-based production needs to be viewed as a journey. “I think we need to temper our expectations of what a cell cultured food is. It is actually quite a wide range of things. It's not going to be the fully textured 3D steak that we see on the market first. It is going to be something akin to a plant-based product with cells involved or cell cultured elements involved. There are a lot of gradations between a plant-based product and a cell based product. We need to be expecting those type of products before we start seeing the things that come to mind first.”

Nevertheless, she added: “Meat is a little more of a transformational change to our food system than these protein products are.”

Consumer acceptance, commercialisation and collaboration

If the development of capabilities is one barrier to scale in cell cultured production, consumer acceptance could present a future stumbling block to commercialisation.

According to a poll of more than 3,100 attendees at the IFF event, only 24% of people polled said they would happily try cell-based agriculture products. Forty-seven percent said they ‘might’ but would ‘need more convincing, while 29% insisted there is ‘no way’ they could be convinced to try cellular products.

Khan argued that communicating around the benefits of cellular agriculture will be key to winning trust.

“Context is everything and that is especially true with future food tech… In all novel technologies communication is going to be important. It will be vital to communicate the benefits of this cell agriculture technology for consumers to understand and accept it. Beyond explaining to consumers how these products are made it is important to explain why scientists and companies around the world are exploring this tech, from environmental benefits to public health benefits.”

Looking to the future development of cellular agriculture, both Khan and Datar expect a growing level of collaboration between innovators in the field and established players in animal protein and related industries.

“There are going to be a lot more partnerships with players in conventional food production from traditional agriculture and meat to the pharmaceutical industry looking to see how they can apply their technology and expertise into this cellular agriculture field and in general future food supply chains. From helping with technical scientific hurdles to even helping distribute or use cell-based products and ingredients down the line, there is massive area of opportunity for traditional food players to collaborate with cellular agri companies,” Khan predicted.

Datar said conventional food makers should ‘absolutely’ look at developments in the space as an opportunity that, she suggested, could be leveraged through investment in the field.

“If COVID has taught us anything this year, it is that the current supply chain is already threatened. The best way to address your threatened business is to diversify, explore new spaces and ways you can continue doing your work.”